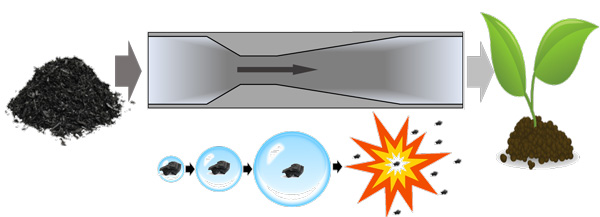

A controlled hydrodynamic cavitation process for the treatment of biochar was experimented for the first time by the Hct-Agrifood Lab, with the aim of improve its physical and chemical characteristics in an economical and rapid way, and making it more effective in use as soil improver.

To obtain biochar with a high porosity and exchange area (BET), in order to raise the contact surface between biochar and soil / plants, it is usually necessary to act on the thermal pyrolysis process (TP), increasing the temperatures, heating speed and residence time.

However, all this has energy costs and effects on yield and on the overall cost-effectiveness of the process, and it also causes other negative effects such as the increase in PH and ash content.

Hydrodynamic cavitation has proved to be a very convenient alternative to high temperature TP treatment. Despite a negligible decrease in the carbon content, the HC process yield was at least one order of magnitude greater than the TP processes and the biochar porosity increased up to 120%.

The results of the experiment were therefore very encouraging, and will be the subject of further study by the laboratory.

Albanese, L., Baronti, S., Liguori, F., Meneguzzo, F., Barbaro, P., & Vaccari, F. P. (2019). Hydrodynamic cavitation as an energy efficient process to increase biochar surface area and porosity: A case study. Journal of Cleaner Production, 210, 159–169. https://doi.org/10.1016/J.JCLEPRO.2018.10.341

Per approfondire

Albanese, L., Baronti, S., Liguori, F., Meneguzzo, F., Barbaro, P., & Vaccari, F. P. (2019). Hydrodynamic cavitation as an energy efficient process to increase biochar surface area and porosity: A case study. Journal of Cleaner Production, 210, 159–169. https://doi.org/10.1016/J.JCLEPRO.2018.10.341