What’s about?

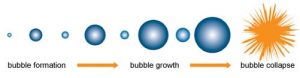

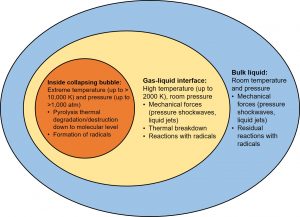

“A blessing in disguise”, as named in a recent scientific article (Shrikant and Khambete, 2017), hydrodynamic cavitation consists of the process of generation, growth, and implosion of vapor-filled bubbles in a liquid, at temperatures below the boiling point. During implosion, extremely reactive microenvironments (hot spots) arise, locally characterized by very high temperatures, intense pressure waves and hydraulic jets, in turn associated to micro-pyrolysis events, and limited generation of oxidant radicals (absent any additive).

“A blessing in disguise”, as named in a recent scientific article (Shrikant and Khambete, 2017), hydrodynamic cavitation consists of the process of generation, growth, and implosion of vapor-filled bubbles in a liquid, at temperatures below the boiling point. During implosion, extremely reactive microenvironments (hot spots) arise, locally characterized by very high temperatures, intense pressure waves and hydraulic jets, in turn associated to micro-pyrolysis events, and limited generation of oxidant radicals (absent any additive).

How is it generated?

Which effects?

Among the fundamental properties of the class of hydrodynamic cavitation-based technologies and processes, some of them assume particular importance:

- Degasification of liquid matrices;

- Remarkable increase of mass and heat exchanges;

- Volumetric and more efficient heating;

- Disintegration – or increase in porosity – of solid substances;

- Remarkable size reduction of oil drops and lipid granules;

- Reduction of surface tension, with consequent increase of the miscibility of different liquids;

- Molecular-scale pyrolysis, depolymerization and degradation of hydrophobic substances;

- Inactivation of the bacterial load, as well as some viruses, at moderate temperatures;

- Increased recovery of metal ores via floatation;

- When coupled with specific additives, generation of powerful oxidation processes.

Application fields

HC technologies are tested and successfully experienced in a wide area of application fields such as, for example, waste water purification and drinking water disinfection, biomass pre-treatment, food pasteurization and sterilization, extraction of bioactive compounds from plant materials, creation of ultra-stable nanoemulsions, and many others.

These technologies have proven to outperform competing methods, significantly increasing process yields, operating either as single unit systems or integrated with other technologies and processes, as well as complying with the principles of green chemistry, as well as green and sustainable extraction methods of natural products.

Main advantages

- Lower construction and management costs

- Superior process yields and energy savings

- Shorter processing times

- Robustness, scalability, reliability and flexibility

- Superior extraction of bioactive compounds

- Reduced use, up to 100%, of additives (solvents, emulsifiers, preservatives, etc.)

- Compliance with the principles of green chemistry and green extraction of natural products.

More info

Meneguzzo, F., Albanese, L., & Zabini, F. (2020). Hydrodynamic cavitation in beer and other beverages processing. In Reference Module in Food Science. Elsevier. https://doi.org/10.1016/B978-0-08-100596-5.23022-9