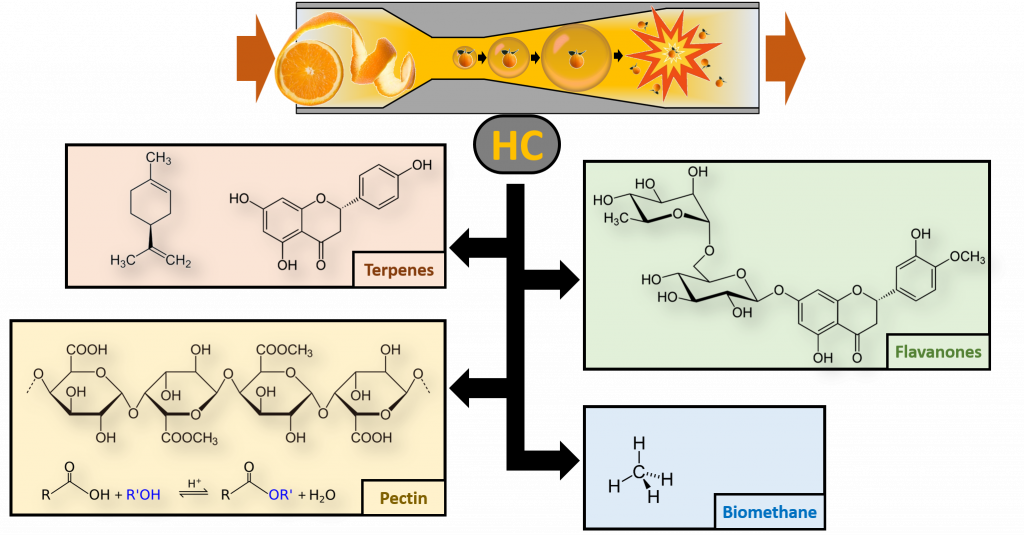

At HCT-Agrifood Lab the HC-based integral extraction of waste citrus peels in water, without any solvent or other additives, was demonstrated directly on the semi-industrial scale using waste orange peels (WOP) and waste lemon peels (WLP).

At HCT-Agrifood Lab the HC-based integral extraction of waste citrus peels in water, without any solvent or other additives, was demonstrated directly on the semi-industrial scale using waste orange peels (WOP) and waste lemon peels (WLP).

In a few minutes, processing only water and waste orange peels at room temperature, a solution was obtained, rich in pectin (with a remarkably low degree of esterification), polyphenols (flavanones and derivatives of hydroxycinnamic acid) and terpenes (mainly d-limonene).

No other processes allowed extracting in just 10 minutes around 60% (w/w) of the overall polyphenol content in fresh waste orange peels.

The solid residue showed an excellent methane generation potential after anaerobic digestion, with a few minutes of process time sufficient to determine a high ratio between the energy contained in the released biomethane and the consumed energy.

The flavonoids extracted in the aqueous phase by the HC processes, along with essential oils and the water-soluble pectin, were isolated via lyophilization of the aqueous solution, affording a flavonoid-rich pectin dubbed “IntegroPectin”. The IntegroPectin showed a very high total polyphenol content that, compared with typical concentration levels in lemon peels, allowed concluding that most of polyphenols, available in the raw material and dominated by hesperidin, are concentrated at the surface of the freeze-dried pectin.

IntegroPectin showed extraordinary antioxidant and antibacterial activities, as well as lack of cytotoxicity, resistance and retention of bioactive properties after extreme heat stress, and extended shelf life. Thus, IntegroPectin appears endowed with a high value as a technical ingredient in plenty of consumer recipes, as well as an active ingredient of food supplements with outstanding, broad-spectrum nutraceutical or pharmacological properties.

The ability of hydrodynamic cavitation of integrally exploiting citrus peel, combined with recent and successful experiences in the HC processing of citrus juice, leads to the immediately feasible perspective of manufacturing integral organic citrus juices. While the production process retains all of the general advantages of hydrodynamic cavitation, these products would be endowed with far higher levels of bioactive compounds and biological activities, higher bioavailability, and enhanced shelf life, representing functionalized or nutraceutical products.

For further information, refer to:

Real-Scale Integral Valorization of Waste Orange Peel via Hydrodynamic Cavitation

Meneguzzo, F.; Brunetti, C.; Fidalgo, A.; Ciriminna, R.; Delisi, R.; Albanese, L.; Zabini, F.; Gori, A.; dos Santos Nascimento, L.B.; De Carlo, A.; Ferrini, F.; Ilharco, L.M.; Pagliaro, M. (2020). Processes, 7(9), 581; https://doi.org/10.3390/pr7090581

Exceptional Antioxidant, Non-Cytotoxic Activity of Integral Lemon Pectin from Hydrodynamic Cavitation. Nuzzo, D., Cristaldi, L., Sciortino, M., Albanese, L., Scurria, A., Zabini, F., Lino, C., Pagliaro, M., Meneguzzo, F., Carlo, M. Di, & Ciriminna, R. (2020). ChemistrySelect, 5, 5066. https://doi.org/10.1002/slct.202000375

Superior Antibacterial Activity of Integral Lemon Pectin From Hydrodynamic Cavitation. Presentato, A.; Scurria, A.; Albanese, L.; Lino, C.; Sciortino, M.; Pagliaro, M.; Zabini, F.; Meneguzzo, F.; Alduina, R.; Nuzzo, D.; Ciriminna, R. (2020). Preprints, 2020030263 https://doi.org/10.20944/preprints202003.0263.v1.